產(chǎn)品詳情

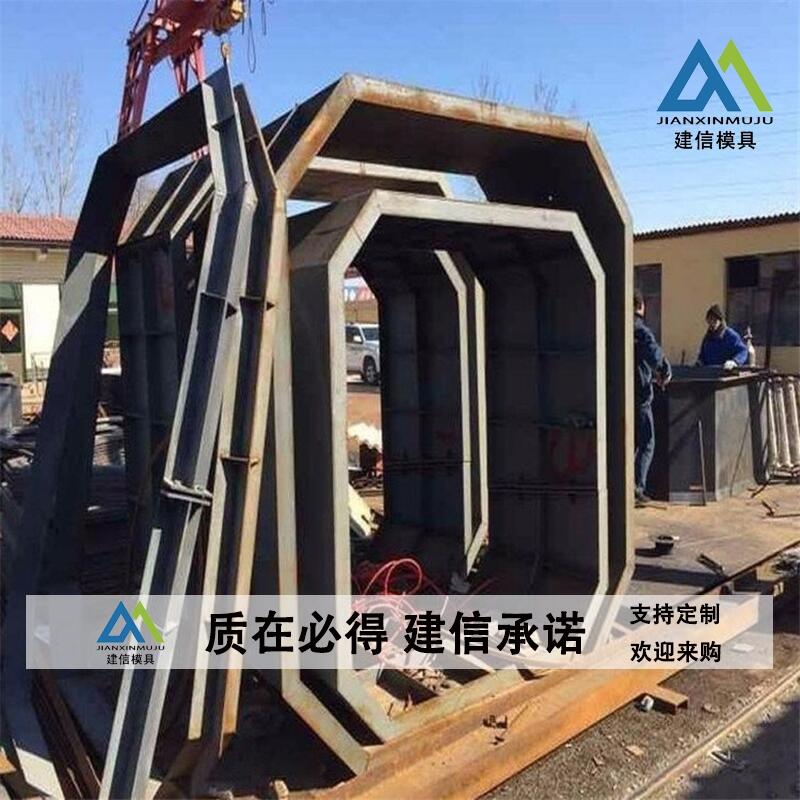

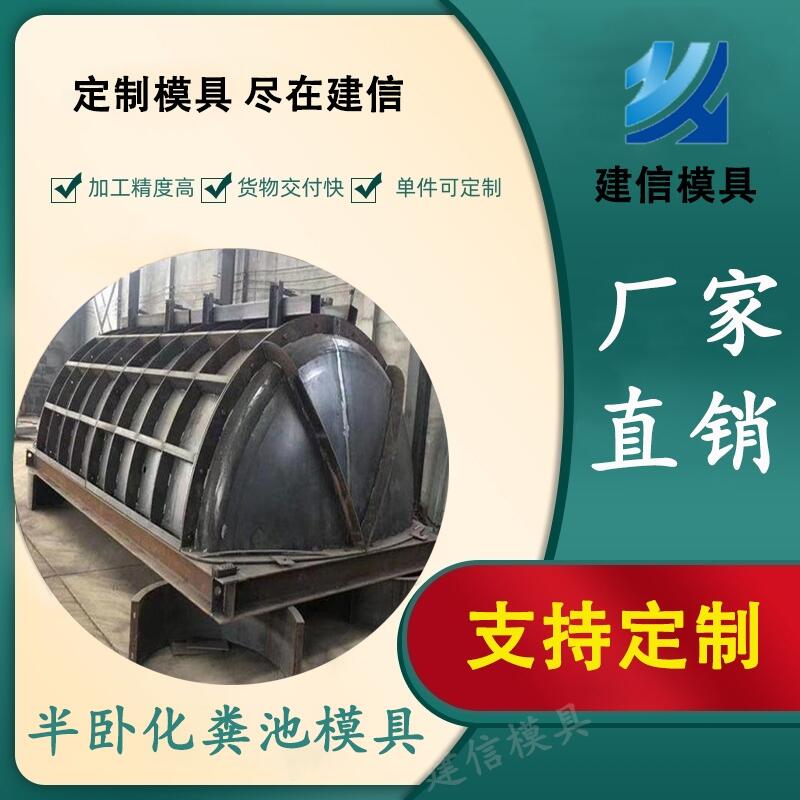

The concrete septic tank mold is used to make septic tanks in places such as single households, schools and tourist attrbs. In order to make a concrete septic tank mold with qualified quality and long service life, we need to pay attention to the following points 1 According to the designer's drawings provided by the customer's needs, the molds with corresponding dimensions are made, and then the molds are used to make the concrete septic tank. The molds include plastic molds and steel molds. Many projects like to choose steel molds because the steel molds have long service time and strong bearing capacity. It is recommended to use steel plates because they are used for a long time compared with ordinary steel plates. 2 During construction, in order to increase the appearance of the septic tank made of the concrete septic tank mold, after the concrete is injected and vibrated, the construction personnel need to smooth its surface with a scraper, and then it is recommended to apply paint, so as to prolong the service time of the septic tank without damage and protect the septic tank. 3 After the concrete is compleby solidified, the mold needs to be cleaned in time after removing the mold. If the clean water is not clean, the mold should be cleaned with diluted oxalic acid in time, then the residual concrete residue on the surface should be brushed with a brush, and the water on the mold surface should be wiped with a special rag to avoid rust, This not only facilitates the next use of the die, but also prolongs the service life of the die.